I still think that levers for each wheel are more important,it would require the affected side to be more engaged. Your hospital should have installed lever wheelchairs ages ago. The reason legs recover faster is that in order to get around to have to use them, lever wheelchairs would provide the same results. Much better arm and hand recovery. Is your hospital so fucking blind they can't see that? Or are they so incompetent they don't know about it?

lever wheelchair (12 posts to May 2016)

rowing wheelchair (7 posts to May 2016)

Do you prefer your doctor and hospital incompetence NOT KNOWING? OR NOT DOING?

A novel push–pull central-lever mechanism reduces peak forces and energy-cost compared to hand-rim wheelchair propulsion during a controlled lab-based experiment

Journal of NeuroEngineering and Rehabilitation volume 19, Article number: 30 (2022)

Abstract

Background

Hand-rim wheelchair propulsion is straining and mechanically inefficient, often leading to upper limb complaints. Previous push–pull lever propulsion mechanisms have shown to perform better or equal in efficiency and physiological strain. Propulsion biomechanics have not been evaluated thus far. A novel push–pull central-lever propulsion mechanism is compared to conventional hand-rim wheelchair propulsion, using both physiological and biomechanical outcomes under low-intensity steady-state conditions on a motor driven treadmill.

Methods

In this 5 day (distributed over a maximum of 21 days) between-group experiment, 30 able-bodied novices performed 60 min (5 × 3 × 4 min) of practice in either the push–pull central lever wheelchair (n = 15) or the hand-rim wheelchair (n = 15). At the first and final sessions cardiopulmonary strain, propulsion kinematics and force production were determined in both instrumented propulsion mechanisms. Repeated measures ANOVA evaluated between (propulsion mechanism type), within (over practice) and interaction effects.

Results

Over practice, both groups significantly improved on all outcome measures. After practice the peak forces during the push and pull phase of lever propulsion were considerably lower compared to those in the handrim push phase (42 ± 10 & 46 ± 10 vs 63 ± 21N). Concomitantly, energy expenditure was found to be lower as well (263 ± 45 vs 298 ± 59W), on the other hand gross mechanical efficiency (6.4 ± 1.5 vs 5.9 ± 1.3%), heart-rate (97 ± 10 vs 98 ± 10 bpm) and perceived exertion (9 ± 2 vs 10 ± 1) were not significantly different between modes.

Conclusion

The current study shows the potential benefits of the newly designed push–pull central-lever propulsion mechanism over regular hand rim wheelchair propulsion. The much lower forces and energy expenditure might help to reduce the strain on the upper extremities and thus prevent the development of overuse injury. This proof of concept in a controlled laboratory experiment warrants continued experimental research in wheelchair-users during daily life.

Introduction

Around 90% of manual wheelchairs users (MWUs) employ a hand-rim propelled wheelchairs (HRW) as primary mode of locomotion for daily living [1]. However, HRW propulsion is a straining and mechanically inefficient mode of transportation. The combination of daily hand-rim wheelchair propulsion and transfers into and out of the wheelchair are thought to be responsible for high upper-limb strains and consequent prevalence of musculoskeletal complaints, oftentimes leading to inactivity [2,3,4,5].

Conventional HRW propulsion has a relatively low gross mechanical efficiency (GME); GME varies somewhere between 3 and 12%, depending among others on environmental conditions, speed, power output, wheelchair design, wheeling experience and propulsion technique [6, 7]. Compared to regular cycling (18–23%) [8] and handcycling (8–20%) [9, 10], hand-rim propulsion is an inefficient mode of locomotion.

The hand-rim wheelchair propulsion cycle is bi-phasic: an active push phase (~ 30% cycle time) and an inactive recovery phase, necessitating a continuous coupling and de-coupling of the hands to the hand-rims. The low fraction of the time for power transfer creates peak levels of force and work [11]. Spatial orientation of the humerus and scapula during HRW propulsion as well as in transfers, increase the musculoskeletal strain and risk of shoulder complaints, especially when they are paired with continued high external loads in daily life (e.g. floor surface, slopes, curb negotiation) [12].

The abovementioned factors suggest that any improvements in the propulsion mechanism and interfacing, may aid in reducing upper-body strains and complaints, while eventually promoting a physically active lifestyle [1, 13,14,15,16,17]. Apart from handcycling [17], few alternative propulsion mechanisms successfully entered and stayed in the marketplace. With ups and downs, lever-propelled wheelchairs have been available over the past 70 years in several different lever propulsion designs. Although crank-lever mechanisms exist [16], the most common designs involve two different levers each propelling one of the rear wheels individually [13]. In such a design, a push to the levers is similar to a push to the hand-rim and the handles can be pulled back during the recovery phase of the propulsion cycle. When tested on physiological performances, these types of wheelchairs proved to be more energy-efficient and less straining than HRWs [14,15,16, 18].

While bi-lever propulsion systems have been experimentally evaluated [1, 13, 14, 18, 19], a bi-manually driven single push–pull lever propulsion mechanism (PPLM) has very scarcely been tested on its physiological and biomechanical merit. The only studies that featured a design with a single lever originated in the 1970s and 1980s [15, 20, 21]. These early crank lever designs were different from the current design, as they were connected to the rear wheels and their cycle frequency was directly fixed to the speed, compared to the freewheel of the current design.

The current study evaluates a new single central-lever push–pull design (rotamobility.com, Fig. 1A). This particular wheelchair design features a gearing system and a free-wheel, with which power can be transferred into forward motion in both the push and pull phases of the propulsion cycle, while it allows steering through the central lever mechanism. Utilisation of both phases of the cycle increases the portion of the propulsion cycle that can be used to exert force, thus theoretically reducing peak strain and potentially energy expenditure (EE) [22,23,24]. Moreover, the different directions of force application allow different muscle groups to be recruited. Therefore, the work is also divided over a larger total muscle mass, reducing strain on individual muscles.

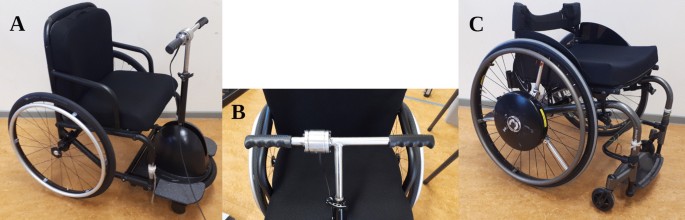

A The prototype of the push–pull single lever propulsion mechanism tested in the current study (RoChair; ROTA Mobility, California). B Close-up of the lever with the integrated unilateral force sensor at the right side. C The Küschall HRW with Smartwheel in the right rear wheel, which functioned as a control

Because of the novelty of the system, the current study does not yet compare experienced users of the PPLM to manual wheelchair users. Since early handrim wheelchair use is accompanied with motor learning processes [25, 26], it is assumed that the novel lever propulsion mechanism may require motor adaptation, skill acquisition and learning as well. Therefore, three research questions were addressed in this study. Firstly, does PPLM have physiological advantages over HRW, looking at EE, GME and HR? Secondly, are the peak forces needed to use an PPLM indeed lower than those needed for propelling a HRW? And finally, does practice change the outcomes of these questions with inexperienced users? These questions will be tested by comparing two inexperienced groups, either using the PPLM and a HRW before and after a practice intervention.

Based on previous studies on lever-propulsion [1, 13, 14, 18, 19], it was hypothesised that the PPLM will be less physiologically straining than a conventional HRW. This is expected to be shown in a higher GME and lower EE and HR. Also, forces that are applied on the lever of the PPLM are hypothesised to be lower than the forces applied on the handrim of the HRW, because the applied forces can be spread over a longer period of time of each full cycle and is divided in a push and pull action, involving different muscle sets. Therefore, equal power can be produced with lower peak forces.

These questions and hypotheses have been tested in a 5-day between-group experiment. In this experiment, 30 able-bodied novices performed 60 min of practice in either the push–pull central lever wheelchair (n = 15) or the hand-rim wheelchair (n = 15). At the first and final sessions cardiopulmonary stain, propulsion kinematics and force production were determined in both instrumented propulsion mechanisms.

More at link.

No comments:

Post a Comment