This is the only way your therapists will be able to objectively determine your movement impairments. From that you could start creating protocols that fix such impairments. But nothing like that will occur because we don't have two functioning neurons in all of stroke leadership. You're screwed.

Squishy Low-Cost Sensors to Monitor Stroke or Sporting Injury Victims

25-03-2020 | | By Rob Coppinger

Reliable, portable, rubber

bonded low-cost electrical components could be fitted to stroke or

sports injury victims’ bodies as part of their rehabilitation at home.

Imperial College London (ICL)

researchers have invented a way to bond a stretchy and squeezy

force-sensitive soft material to electrical components. They created a

bond between the soft material and components that is so strong the

stretchy rubber material breaks before the bond between the components

and rubber does. Adhesives have been used previously to try to bond the

rubber material, which is conductive, to electrical components, but they

broke down when the two materials were pulled apart.

“We hope [our] method will allow us to make low-cost soft

sensors that are reliable and portable, that can be used to monitor

people’s health in their own homes,” said ICL Department of Bioengineering researcher,

Michael Kasimatis. “Such sensors could be coupled with a mobile device,

such as a smartphone so that the data they generate can be easily

processed and stored on the cloud, which is important for applications

in digital healthcare.”

Stretchy Resistance

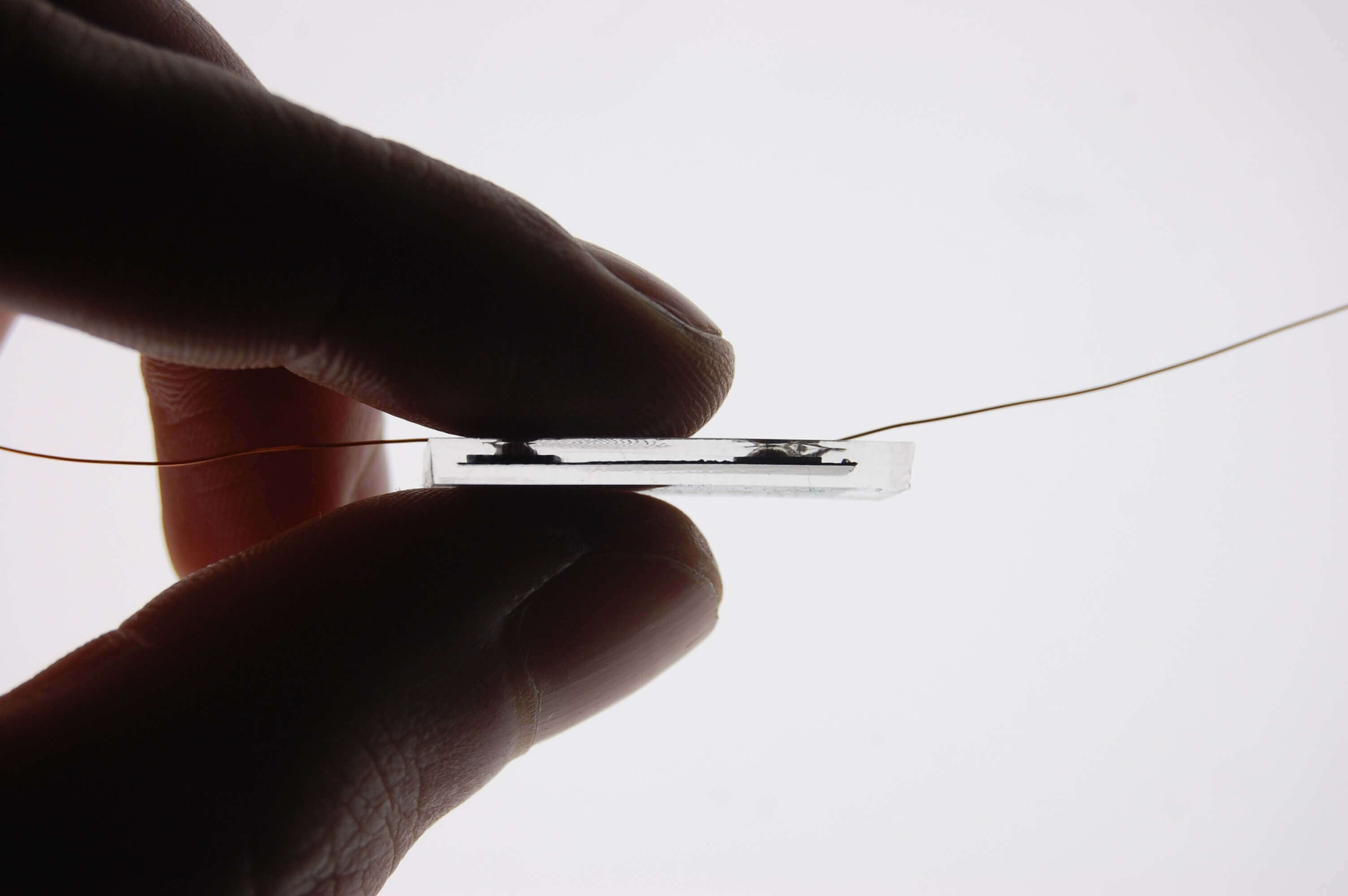

The ICL researcher’s new method is to use metal-coated

silicon which triggers a chemical bond with the stretchy and squeezy

rubber. The silicon contacts are smooth on one side, where they bond to

the rubber, and pitted and plated with copper on the other side, so

wires or other electric components can be easily attached using

conventical methods, such as soldering. The ICL research team is seeking

partners to advance technology.

The Squishy Sensor

A few healthcare and rehabilitation prototype sensors have

been tested to demonstrate how the bonding method can resist the strains

of repeated stretching. The prototypes included a wearable breathing

monitor, a leg band for exercise monitoring and a squeezy ball for hand

rehabilitation. A squeezy ball is viewed as a potentially very useful

rehabilitation tool and soft electrical force sensor as it can be used

by patients with hand injuries or neurological disorders.

While such sensors have been in development for a long

time, none have been commercialised because it has been difficult to

integrate them with the electronic components, such as the wires,

microchips and the batteries; all of which are needed to collect,

process, analyse and transmit the data the sensor has been collecting.

With the successful demonstration of the new bonding technique and its

application to laboratory prototypes, the research team are planning to

take the technology out of the lab and commercialise it.

No comments:

Post a Comment