They never say if this will be able to provide 100% recovery in the time you'll be able to use this in the hospital.

Mechanical Design and Analysis of the End-Effector Finger Rehabilitation Robot (EFRR) for Stroke Patients

1 Parallel Robot and Mechatronic System Laboratory of Hebei Province, Yanshan University, Qinhuangdao 066004, China

2 Key Laboratory of Advanced Forging &

Stamping Technology and Science of Ministry of Education, Yanshan

University, Qinhuangdao 066000, China

3 Academy for Engineering & Technology, Fudan University, Shanghai 200433, China

4 State Key Laboratory of Robotics and System, Harbin Institute of Technology, Harbin 150080, China

5 College of Arts & Design, Yanshan University, Qinhuangdao 066004, China

*

Author to whom correspondence should be addressed.

Academic Editor: Giovanni Legnani

Machines 2021, 9(6), 110; https://doi.org/10.3390/machines9060110

Received: 26 April 2021 / Revised: 19 May 2021 / Accepted: 24 May 2021 / Published: 26 May 2021

(This article belongs to the Special Issue Design and Control of Advanced Mechatronics Systems)

Most existing finger rehabilitation robots are structurally complex and

cannot be adapted to multiple work conditions, such as clinical and

home. In addition, there is a lack of attention to active

adduction/abduction (A/A) movement, which prevents stroke patients from

opening the joint in time and affects the rehabilitation process. In

this paper, an end-effector finger rehabilitation robot (EFRR) with

active A/A motion that can be applied to a variety of applications is

proposed. First, the natural movement curve of the finger is analyzed,

which is the basis of the mechanism design. Based on the working

principle of the cam mechanism, the flexion/extension (F/E) movement

module is designed and the details used to ensure the safety and

reliability of the device are introduced. Then, a novel A/A movement

module is proposed, using the components that can easily individualized

design to achieve active A/A motion only by one single motor, which

makes up for the shortcomings of the existing devices. As for the

control system, a fuzzy proportional-derivative (PD) adaptive impedance

control strategy based on the position information is proposed, which

can make the device more compliant, avoid secondary injuries caused by

excessive muscle tension, and protect the fingers effectively. Finally,

some preliminary experiments of the prototype are reported, and the

results shows that the EFRR has good performance, which lays the

foundation for future work.

Keywords:

finger rehabilitation robot; mechanical design; adduction/abduction movement module; adaptive impedance control; preliminary tests

1. Introduction

According

to the World Health Organization (WHO), there are more than 15 million

people around the world suffer strokes every year, and about 5 million

of them are permanently disabled. Moreover, the global lifetime risk of

stroke from the age of 25 years onward has increased from 22.8% in 1990

to 24.9% in 2016. Stroke is still the main cause of death worldwide [1,2,3].

Stroke causes damage to the nervous system, and can cause patients to

lose part or all of their ability for activities of daily living (ADL),

which brings a heavy burden to the family and society. Currently, the

functional impairment of the fingers poststroke is rarely considered

life-threatening. Together with the limited resources (time, cost,

number of the caregivers and equipment etc.), it rates low on the

priority of rehabilitation tasks [4,5,6].

In some ways, this increases the number of people with finger injury

sequelae. Therefore, research on finger rehabilitation after stroke

should be given more attention.

Rehabilitation

robots can assist poststroke patients with continuous, repetitive

training with a standardized process, reducing the workload of

therapists and providing more clinical options for patients. Hand

rehabilitation robots can be divided into end-effector devices,

exoskeletons and glove type in terms of wearing form [7]. Among all the end-effector devices, Amadeo [8,9] is the most commercially successful hand rehabilitation robot available. HandCARE [10]

adopts ropes to fix fingers, and a clutch system is designed to allow

all the fingers to be driven by only one motor. Rutgers Master II [11]

is a four-degree-of-freedom pneumatically driven finger rehabilitation

device which has been clinically tested. It achieves active

flexion/extension (F/E) motion for four fingers, and the maximum output

force can reach 16.4 N. Reha-Digit [12]

is a passive rehabilitation device: patients need to put the fingers

into four plastic roller sets during the training process. SAFE [13]

drives the patient’s fingertips to do rehabilitation exercises by using

rigid connecting rod structures. In addition, some universities have

conducted researches on end-effector finger rehabilitation devices [14,15]. As for the exoskeletons, the robot developed by Gifu University [16]

controls all of the fingers independently by arranging side-by-side

dual motors on the back of the hand. The researchers at the University

of Texas at Austin [17,18]

applied the series elastic actuator (SEA) to finger rehabilitation.

Their device uses Bowden cables to transmit power and obtains joint

information through angle sensors, and it is lightweight and

easy-to-wear by moving the motors outside of the back of the hand. The

rehabilitation robotic exoskeleton hand [19]

realizes finger F/E training through two worm gears, and passive pins

are set to achieve adduction/abduction(A/A) motion simultaneously and a

virtual reality system has been developed for rehabilitation scenarios.

The Powered Finger–Thumb Wearable Hand Exoskeleton [20]

adopts an under-driven cord control form and designed a self-alignment

mechanism that prevents misalignment for the joints between the human

and machine, besides, parallel mechanism has been attempt to applied on

the hand rehabilitation [21].

The glove-type devices have developed significantly in recent years due

to their good adaptability. Their driving form includes pneumatic [22,23], cord drive [24], layered reed drive [25,26,27] and so on.

Force-based control is one of the control strategies for finger rehabilitation robots [28]. Cheng et al. [29]

proposed a controller combing the iterative learning control (ILC) and

the active disturbance rejection control (ADRC) to adapt the repeating

training manner and overcome the external interference in a wearable

hand rehabilitation robot. Park et al. [30]

used proportional-integral-derivative (PID) control to design a control

strategy capable of automatically switching between position and force

control. Chiri et al. [31] utilized the PID control strategy to compensate for the external forces exerted by the patient on the robot. Huang et al. [32]

proposed a variable integral PID (VIPID) controller to track the

patients’ finger trajectory which has better performance than the

conventional ones. Jones et al. [33]

used a PI controller to compensate the auxiliary torque for fingers,

and the control of either position or torque can be implemented in this

device. Polygerinos et al. [34]

presented a sliding-mode controller (SMC) for their finger

rehabilitation robot with the obvious advantage of not requiring an

explicit model of the system for the synthesis of the controller.

The

large number of degrees of freedom (DoF) and strong interjoint coupling

in human fingers make the development of finger rehabilitation robots

difficult, leading to the complex structure and difficulty in wearing

most of the existing devices. The inability of the fingers to perform

A/A motion is one of the signs of nerve damage [35],

which affects the patient’s ability to ADL. The active A/A exercise can

carry out targeted muscle strength training on the palmar interossei

and the dorsal interossei, and fully open the range of motion of the MCP

joint [36].

However, few existing robots can achieve active A/A training and cannot

fully open the joint mobility of the fingers, which affects the

rehabilitation outcome and patient experience. As for the control

strategy, it is mainly based on the PID, and the corresponding strategy

is developed for the characteristics of the developed equipment.

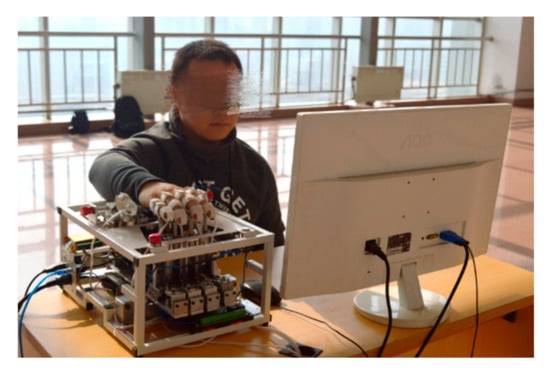

This paper presents the design and development of an end-effector finger rehabilitation robot (EFRR) (see Figure 1).

EFRR utilizes a fixed pulley-track module for finger F/E motion, and a

novel synchronous pulley set has been proposed for active A/A motion

driven by a single motor. This allows patients to open up their joint

mobility fully. EFRR has two thumb rehabilitation structures with

left/right symmetry, which makes it possible for functional impairment

of the left/right hand to train on the device and can reduce the cost

greatly. The design above is also the result of a comprehensive

consideration of wearing convenience, hand weight bearing, and

manufacturing cost. In terms of control strategy, an adaptive control

strategy based on fuzzy PD is designed according to the characteristics

of the EFRR, which makes it compliant during the training process and

ensures the safety of patients.

Figure 1.

Prototype of the EFRR. EFRR: end-effector finger rehabilitation robot.

The rest of this paper is organized as follows. Section 2 presents the innovative structural design of the EFRR, including the design principles and rationale; Section 3 introduces the adaptive control strategy based on fuzzy PD; Section 4 shows the preliminary experiments conducted at the EFRR and the related analysis; finally, Section 5 concludes this study and provides suggestions for future work.

More at link.

No comments:

Post a Comment